Large scale manufacturing of marine maintenance platforms for a government agency

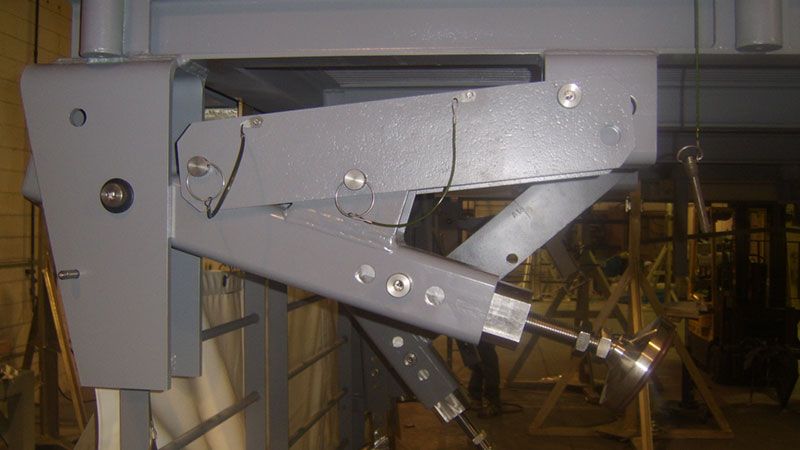

AC, Inc. produced a marine maintenance platform that consisted of three large subassemblies for a government agency. The subassemblies themselves in this large scale manufacturing project measured approximately 8’ x 12’, 8’ x 12’ and 10’ x 24’. Each subassembly had to be able to attach to the vessel individually; yet remain closely positioned to each other so that personnel could walk between all three subassemblies to perform various maintenance functions while the vessel was in port. AC, Inc. went on to manufacture 12 of these completed units and delivered them to both coasts.

The project had several components that made manufacturing difficult.

Over 200 pages of cross-referenced, highly detailed drawings

First, the cache of drawings for the project presented a challenge because of the number of drawings and their detail. All the individual components were presented within the assembly level document; dimensioned in the assembly or sub-assembly stage; referenced from sheet to sheet and section to section; and contained approximately 200 pages, along with associated tangential products.

A wide range of varied and distinctive materials and sizes

Second, the materials required by the project were varying and distinctive. Those materials included High Strength Steel, Stainless Steel, Stainless Steel Grating, Carbon Steel and Delrin in various sizes of bar, plate, sheet, rod and tube. These materials were all manufactured to non-standard specifications and purchased with full metallurgical testing and traceability.

Complex welding requirements requiring outside certification

Third, the welding consisted of over 97 preassigned joint configurations that required outside certification of operators, equipment and processes. The complete welded assembly was proof-loaded up to 15,500 pounds and subjected to post load magnetic particle inspection of selected critical joints.

Finishing and assembly for high performance in a harsh marine environment

Finally, the completed weldments were sandblasted and painted to withstand a harsh marine environment and brought to completion by assembling over 300 various bolts, screws, nuts, chains, identification tags, fasteners and rails.