AC, Inc. has a fully integrated manufacturing facility located in Huntsville, Alabama, with sheet metal, machining, welding, blasting, painting and final assembly capabilities.

Facility at a Glance

- 12-acres of property

- 100,000 sq. ft manufacturing space

- 6,500 sq. ft fully equipped office space

- 22,500 sq. ft storage space

Sheet Metal Shop

AC, Inc. can cut, shear, notch, and bend aluminum, steel, and stainless steel. We have the ability to program and maintain excellent repeatability on difficult parts with our CNC brake press.

- Shearing capacity up to ⅜” and 12’

- Variety of power press brake equipment – 150 ton/17’ capacity

- CNC brake press capacity up to 12’

- Two CNC automatic band saws

- Two 7.5hp radial arm saws

- Metal roller - capability up to 144”, ½” thick

- Laser cutting and water jetting partners in place for material beyond ½” thick

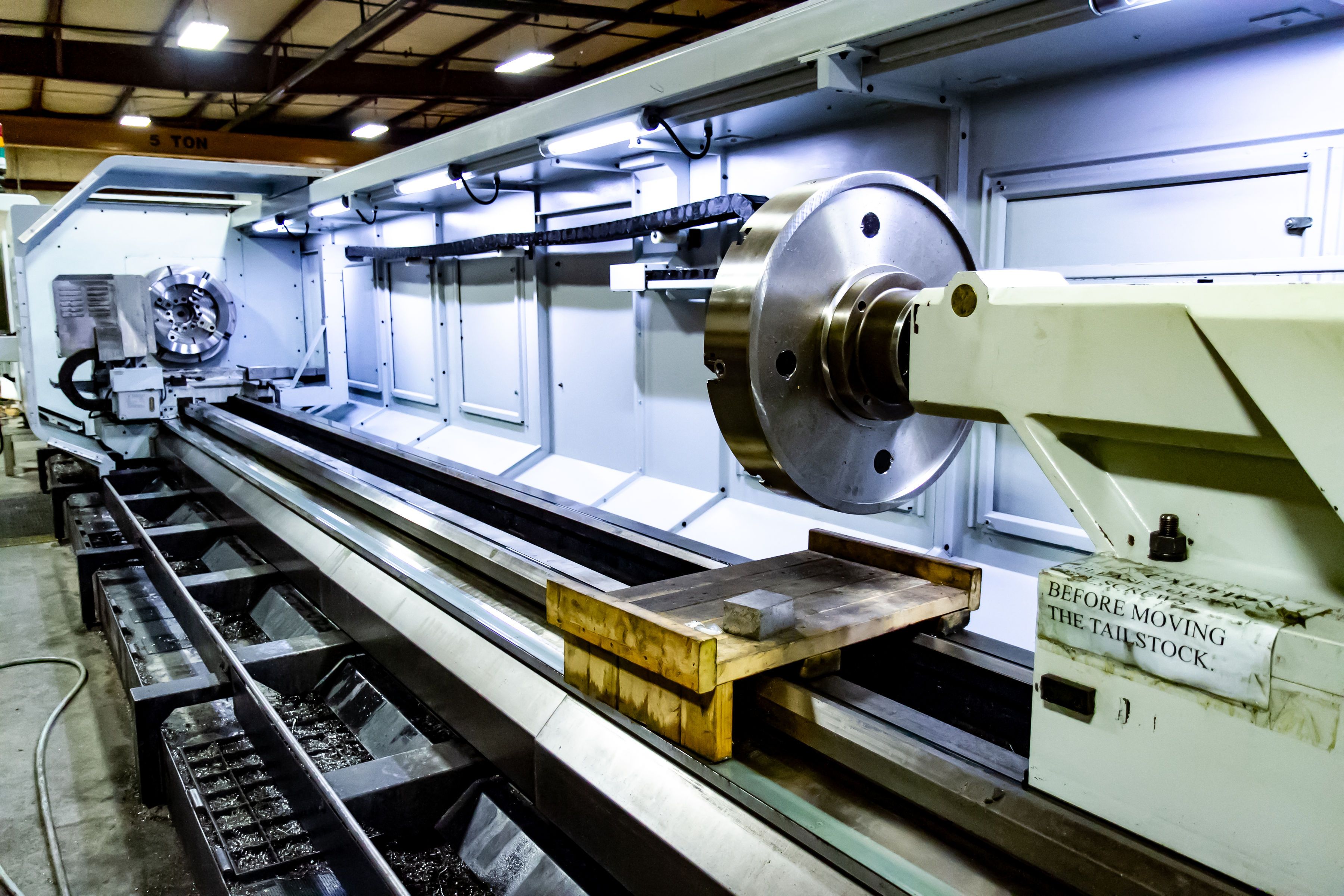

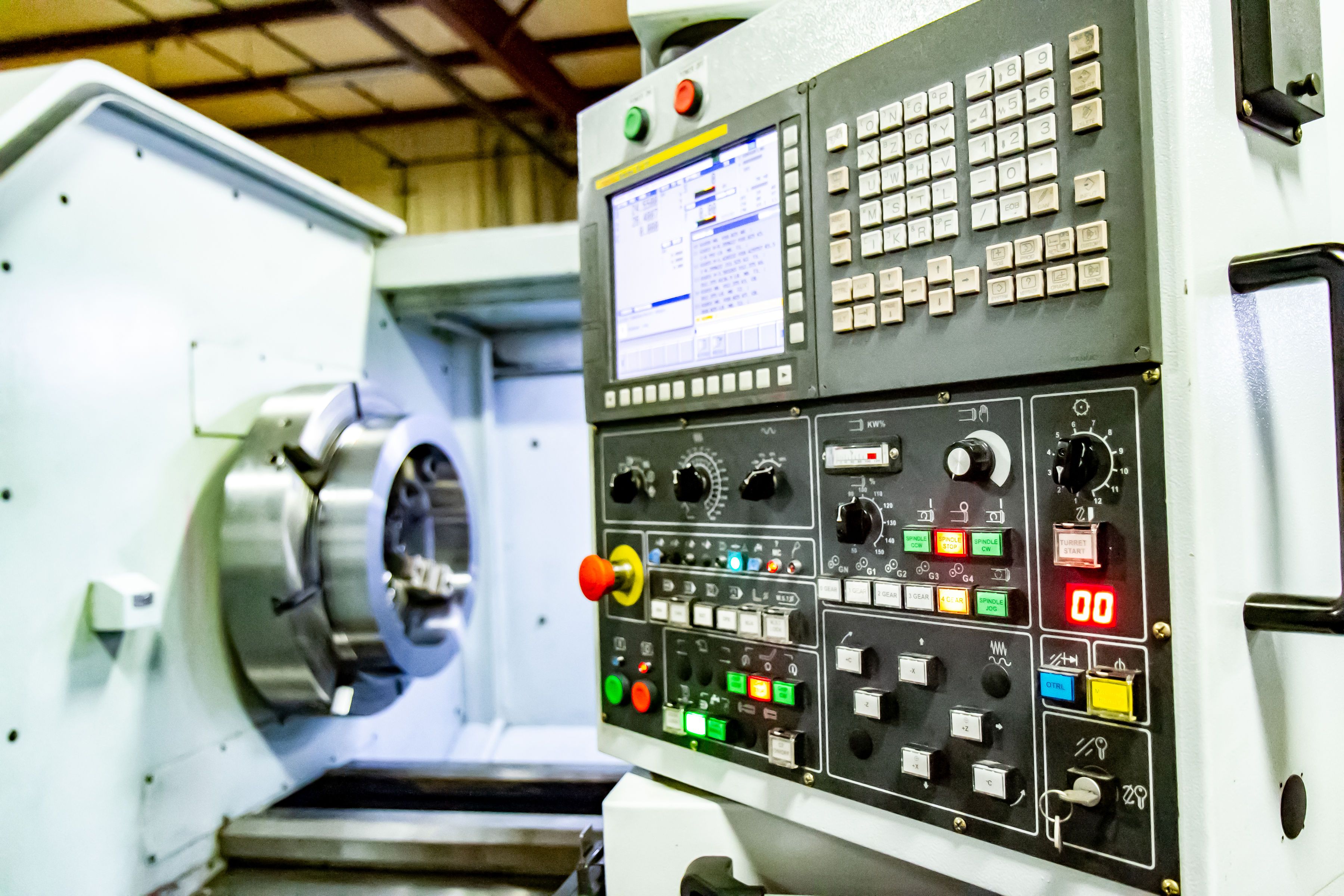

Machine Shop

AC, Inc.’s machine shop is capable of handling jobs of all sizes, including very large components. Materials we can handle include aluminum, steel, stainless steel, high strength steel, and various composites.

- CNC lathe 36" bar feeder

- Six 3-axis Fadal CNC milling centers with slide tables for vertical machining (300” capacity)

- Skoda manual lathe – 28” swing, 26 ft center-to-center capacity

- Numerous vertical & horizontal manual milling centers and drill presses

- Large CNC Lathe - Cf Axis, 45" swing over the bed, 354" distance between centers, 22" bed width, Fanuc Oi control, 40HP spindle motor, 6" spindle bore.

Weld Shop

AC, Inc. can perform layout and fit-up of small or large components to various military or commercial standards.

- State-of-the-art OTC robotic welder with positioners and 35” x 35” dual table

- Variety of GMAW and GTAW welders

- Five ton overhead crane

- Welder qualifications are to AMS Standard #1595, (steel and aluminum), AWS D1.1, AWS D1.2, AWS B2.1, AWS D1.3, AWS D1.6 AWS D17.1 and SAE-AMS-STD-2219. In addition, some are also qualified per TACOM 19207-12472301 (armor aluminum)

Surface Finishing

AC, Inc. has the ability to coat or recondition products to meet a variety of military and commercial standards.

- Powder coat paint line, including CARC

- Two manual paint lines

- Sand/glass/bead blast capabilities up to 30 feet in length

- MIL-C-53039 Wet Coat CARC, MIL-STD-1303 Enamels for Naval Ordnance Equipment, MIL-PRF-32348 Powder Coat CARC; (others as contracts require)

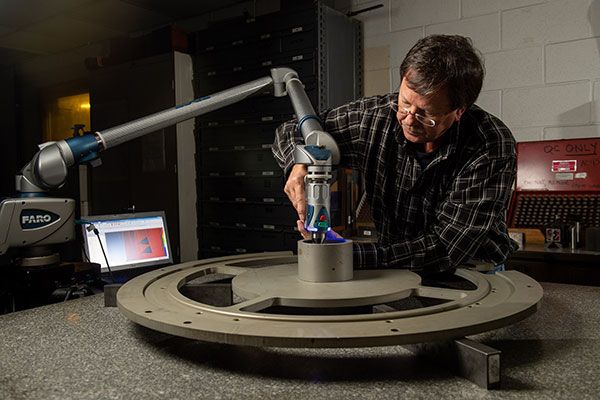

Quality Control

AC, Inc. has a certified quality system and can provide complete documentation packages. Learn more about our Quality Department.

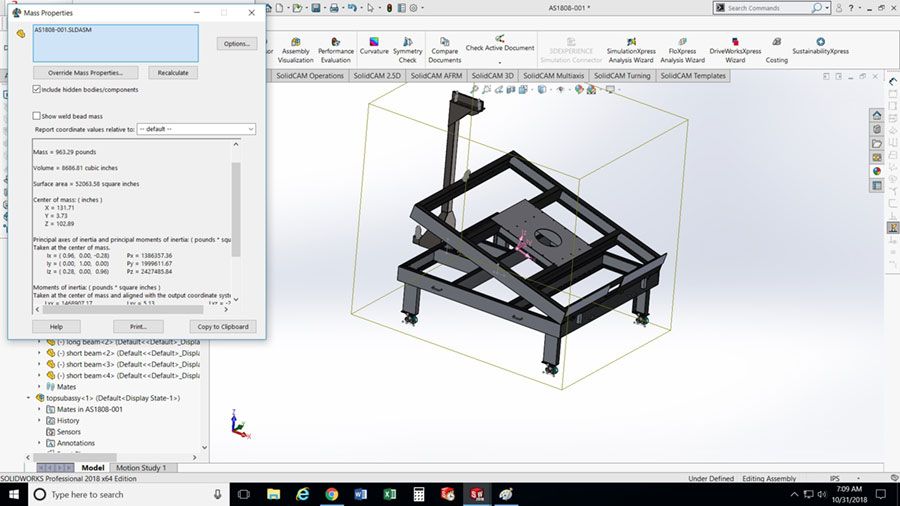

Engineering

AC, Inc. is experienced in interpreting difficult or vague drawings to ensure the end products match the need...

- SolidWorks

- SolidCAM

- Modeling & simulation

- Drawing development